Lift Safety

Learn about lift maintenance safety and control measures.

Lifts

Many of us, who live in tall apartment buildings or work in high-rise offices, use lifts or elevators every day. The high concentration of tall buildings in Singapore has made lifts an essential mode of vertical transportation.

Lift Maintenance

All lifts require regular maintenance to ensure smooth and safe operation. Without adequate maintenance, lifts would cause inconvenience to users and expose lift maintenance personnel to unnecessary risks.

Lift maintenance work generally covers:

- Routine maintenance (lubrication, cleaning, inspection, alignment, etc.)

- Non-routine maintenance (emergency repair, replacement of worn or damaged components, re-calibrating load cell, etc.)

Hazards and Controls

Some common hazards in lift maintenance work include:

|

Hazard |

Controls |

|

Pinching (e.g. fingers pinched when ropes come into contact with pulley or sheave)

|

|

|

Electrocution (e.g. worker coming into contact with non-finger safe terminal block)

|

|

|

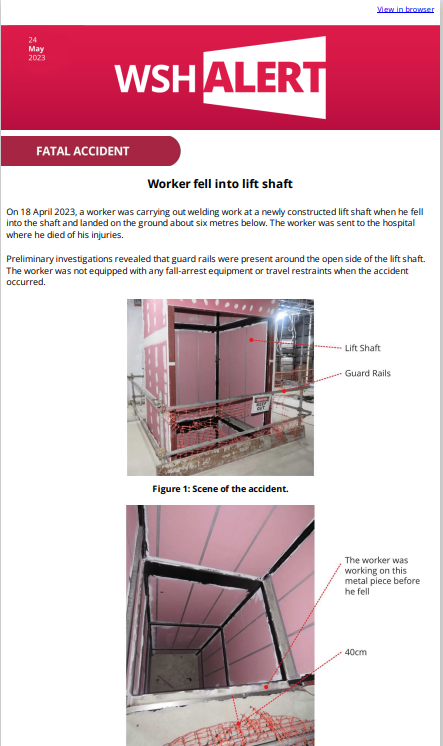

Fall from height (e.g. falling off from the top of the lift car to the bottom of the lift pit)

|

|

|

Heat stress (e.g. worker perspiring in hot motor room)

|

|

For More Information

- SS 550: Code of practice for installation, operation and maintenance of electric passenger and goods lifts

- WSH Guidelines on Working safely during maintenance of electric passenger and goods lifts (PDF)

- WSH Guidelines on Working safely during modernisation, installation or dismantling of electric passenger and goods lifts (PDF)